Manual to Automated

Conversion by Crossmuller

Upgrade your plant or factory from manual or semi-manual processes to fully automated, digitally controlled systems—improving productivity, quality, and scalability.

Why Convert Manual Processes to Automation?

Many manufacturers still depend on manual handling, data entry, and process control—leading to higher labor costs, inconsistent output, and limited real-time data. By converting manual operations to automation, you unlock:

Increased throughput and consistent product quality

Lower risk of error, injury, and production delays

Real-time monitoring, analytics, and traceability

Labor redeployment for more strategic, high-value tasks

Future-ready scalability and rapid changeover

Proven Technology in Action

The Crossmuller Solution

Every successful automation journey begins with a tailored roadmap. Crossmuller’s process includes:

Comprehensive Process Audit:

We assess your manual workflows, bottlenecks, and upgrade opportunities.Automation Feasibility Study & ROI Analysis:

Transparent evaluation of the business case for automation, including payback period and operational benefits.Custom Automation Design:

Engineering solutions for sensors, conveyors, robotics, control panels, and MES/SCADA integration—suited to your factory’s layout and product needs.Project Delivery & Installation:

Our in-house teams manage equipment procurement, mechanical installation, electrical wiring, programming, and on-site commissioning—ensuring a seamless transition.Training & Support:

Operators and managers are trained on new automated processes, with all documentation and aftercare provided.

Real Results You Can Benchmark

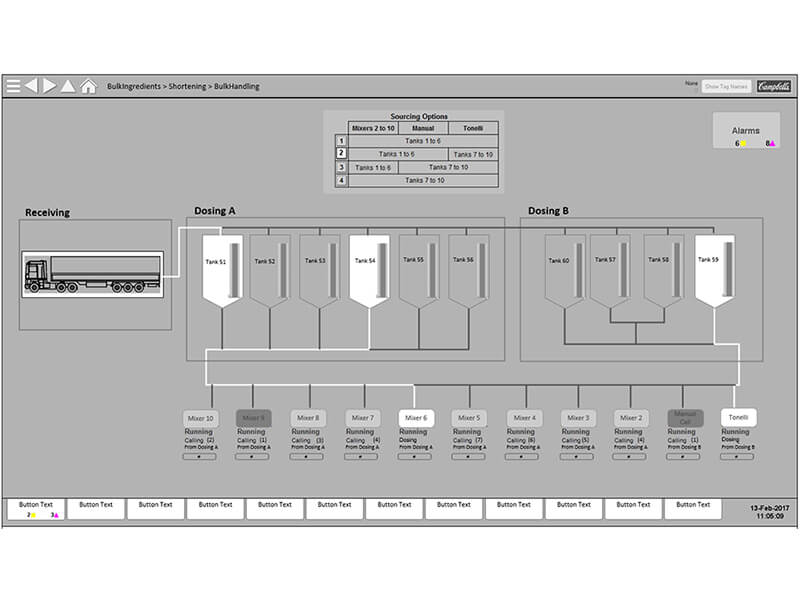

At Arnott’s Virginia (QLD) biscuit facility, Crossmuller successfully modernized the Ingredients Handling System (IHS)—the central control solution for one of Australia’s largest snack food plants

Crossmuller was engaged to replace the aging automated ingredient control system, which had reached end-of-life and suffered from fragmented modifications and unreliable documentation. The project entailed a full upgrade of PLC hardware and SCADA infrastructure, moving to a modernized platform using Wonderware System Platform, Recipe Manager Plus, and Allen-Bradley GuardLogix PLCs

To minimize production impact, Crossmuller executed the upgrade in phases. Hardware and PLC changes were separated from SCADA migration, with thorough testing carried out before final commissioning. Over a 12-month execution plan, control code was gradually migrated; during the plant’s Christmas shutdown, the system was commissioned over two weeks—and resumed nearly full production within just one day

Crossmuller also installed 26 high-resolution touch-screen operator terminals, including ten at mixer stations running a hybrid InTouch / Recipe Manager Plus interface. This provided operator-level visibility into IHS operations and allowed direct recipe selection at the mixer—enhancing flexibility and control across over 200 recorded recipes

Outcome:

Seamless legacy automation upgrade with zero production downtime

Enhanced recipe control across mixers for improved quality and traceability

Robust, documented control system based on supported automation platforms

Elevated operator visibility, system diagnostics, and ongoing maintainability

Key Benefits in a glamce

Lower production costs and higher margins

Improved safety and workplace conditions

Real-time, accurate production data

Fast changeover and reduced downtime

Compliance with Australian standards

why CROSSMULLER?

Unlock higher efficiency, consistent quality, and real-time control by converting manual or semi-manual processes into fully automated production lines. With Crossmuller as your automation partner, you’ll gain a custom solution engineered to streamline operations, reduce risk, and position your business for scalable, future-proof growth.

Frequently Asked Questions

Item #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Item #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Item #3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Taking the Next Step

Don’t let manual bottlenecks hold your business back.

Contact Crossmuller today for an automation assessment and discover how a manual to automated conversion can boost your plant’s efficiency, safety, and long-term success.

- Phone: 1300 300 540

- Email: sales@crossmuller.com.au

Crossmuller acknowledges the Traditional Owners of the lands across Australia as the continuing custodians of Country and Culture. We pay our respect to First Nations peoples and their Elders, past and present.

Quick Links

Get In Touch

A Borg Company | © 2025 Crossmuller | All Rights Reserved

Privacy Policy

|

Terms & Conditions